In the mining sector as elsewhere, companies are increasing their efforts to reduce their greenhouse gas (GHG) emissions. Several mining companies are also making ambitious carbon footprint commitments that even go as far as carbon neutrality. The adoption of hydroelectricity and other types of green energy is therefore becoming unavoidable.

ArcelorMittal, which extracts iron and produces iron concentrate as well as iron oxide pellets for the steel market, announced at the end of April that it was the first mining company in Quebec to acquire a fleet of electric buses to transport its employees from Fermont to the Mont-Wright mine.

While some employees use their own vehicle to get to work, ArcelorMittal has also installed a dozen charging stations in Mont-Wright and at the Port-Cartier pellet plant.

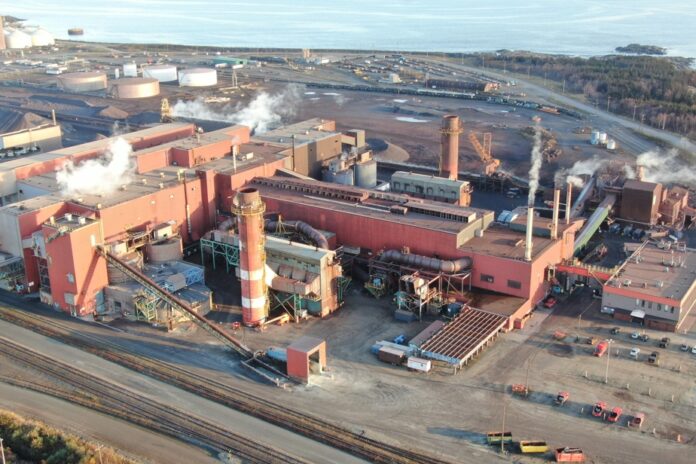

The company, which has committed to reducing its GHG emissions by 25% by 2030 and to achieving carbon neutrality by 2050, is also working on larger projects. ArcelorMittal’s largest source of GHG emissions on the North Shore is pelletizing, with over 1 million tonnes of CO2 emitted per year.

“No less than 70% of these emissions come from the coal that we use in the process and 30% come from the heavy fuel oil that we use to fuel the furnaces and from additives,” said Mapi Mobwano, President and CEO. of ArcelorMittal Mining Canada.

Last year, ArcelorMittal began using pyrolytic oil, produced from residues from the lumber industry, to replace heavy fuel oil. “We are the first pellet plant to use pyrolytic oil continuously and so far we have used 8 million liters of it, which is equivalent to taking the equivalent of 2,400 cars off the road,” says Mapi Mobwano.

“Using pyrolytic oil will allow us to reduce our emissions by 25%,” says Mapi Mobwano.

To achieve carbon neutrality, the company will tackle coal. “We are looking at how to substitute it with biochar from forest biomass,” he adds. We want to get the wood affected by the spruce budworm. The technology exists, especially in Brazil, but there are very few producers in Quebec. We are looking for partners. »

Each mining company must adapt its GHG reduction strategy according to its reality. For example, in Nunavik, where the Hydro-Quebec grid is not accessible, Glencore’s Raglan Mine installed two 90-meter wind turbines to reduce its diesel consumption. They produce 10% of the energy consumed in mine operations.

For example, Agnico Eagle installed an electric conveyor for its ore to use fewer trucks at the Goldex mine in Val-d’Or.

But Josée Méthot, CEO of the Quebec Mining Association, notes that there is still technology development to be done for the industry. “Not all equipment is electric,” she says. For example, 425 ton trucks still run on diesel. Converting them to electricity will require very powerful batteries. »

All the same, most mining companies make a commitment to carbon neutrality. Some for 2050, others before. For example, Nouveau Monde Graphite is committed to 2030. “For new projects that are emerging, this commitment has practically become a standard,” says Ms. Méthot. This does not mean that mining will not produce GHGs, but they will minimize them and they will offset them. »