This was the ambitious project that Simon Larochelle set for himself in 2019, president and CEO of Royer, manufacturer of functional shoes for work and the military sector.

Founded in 1934 by Louis-Philippe Royer, the firm has since operated a factory in Lac-Drolet, near Lac-Mégantic. But to provide the means to achieve this ambitious objective, a new factory was built in Sherbrooke and inaugurated in 2019. It had become necessary to achieve the capacity required to meet demand. The first boots left the factory in January 2020.

“We had to completely review the production period and then design the product,” says Simon Larochelle. “It’s process engineering first before infrastructure. You have to dream of the ideal process, then think about the required infrastructure, and finally build a new factory and not renovate,” he explains.

A complete digital transformation has accompanied all these changes. This was digital integration. The entire management process has been integrated. All data was brought together in one place where all staff could view it. “This was essential to avoid both errors and loss of efficiency,” he says.

Starting a fully integrated factory was not easy, he recalls. Royer was supported by Productique Québec, the college technology transfer center of the Cégep de Sherbrooke, made up of a team of experts from various fields.

First, the choice of a management software package, i.e. the tool that will make it possible to manage the company based on a common database. Then, an artificial intelligence (AI) research project led by Productique Québec, to determine how to implement AI for manufacturing purposes. And finally, the firm underwent a digital audit to determine if it was fit and ready to operate.

Despite the complexity and the need for help that it creates, the bulk of the project must be carried out internally, recalls Simon Larochelle.

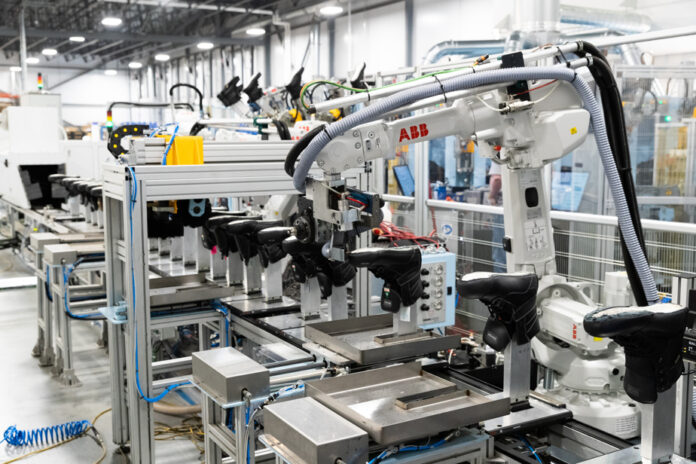

At Royer, we were well aware that the digital transition accompanied by the development of robotics also had its share of problems, including that of a risk regarding the quality of the product. It is humans and not robots who can ensure the quality of the product, recalls Simon Larochelle. “Using more robots and fewer humans in the production process necessarily leads to a reduction in vigilance regarding product quality,” he says. It is important to remember that the key to success lies in vigilance regarding product quality. »

“All Royer shoes meet very strict safety standards and are continually subjected to the tests required to display the approval labels they display,” we can read on the firm’s website.

As we approach the objective of multiplying production by five, even before the planned date, we have decided to slow down production somewhat, precisely because of a quality issue. We are putting the emphasis back on quality to ensure that we maintain the standard that has made the company famous.